Introduction:

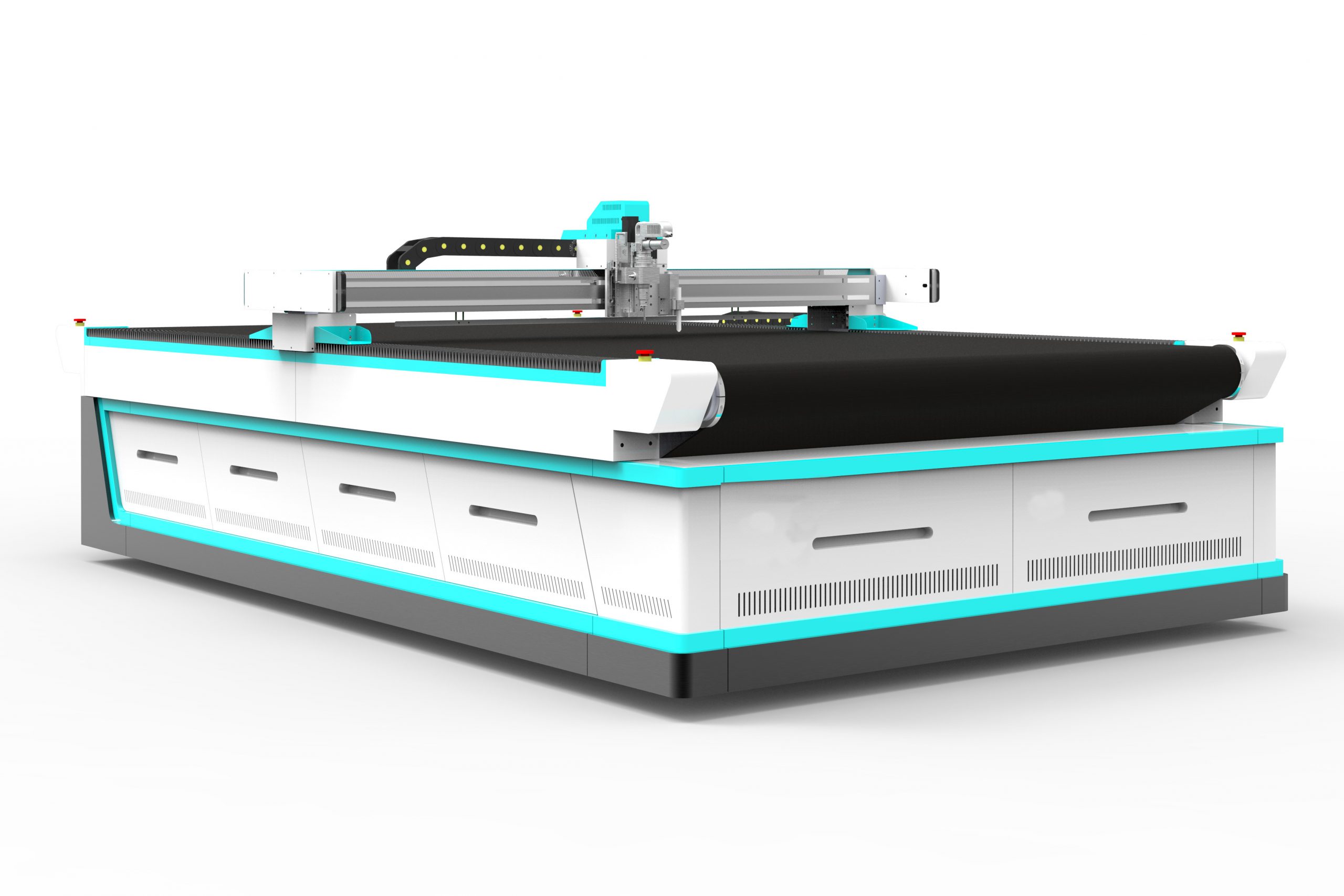

Equip one Auto feeding felt worktable, could feed materials to worktable automatically, so except processing the materials like flat worktable(rubber, cellular board, KT board, foam, sound insulation sponge,Carbon fiber plate, soft wood, paper,Logo.etc), also is specialize in cutting roll of materials such are various fabric, cotton, textile, leather.etc. Widely used in clothes, shoes,furniture, decoration.etc. The models could be custom-made, just the max width could max be 2000mm.

Technical parameters:

| Model | 1612 | 1625 | 1625-Double Beam |

| Working size | 1600*1200mm | 1600*2500mm | 1600*2500mm |

| Knife Cutter | Oscillating knife cutter/Rotary knife cutter, Pneumatic knife cutter/Press roller/Creasing cutter/ Kiss cutter/ Punch tip/Drill Spindle/Camera | Oscillating knife cutter/Rotary knife cutter, Pneumatic knife cutter/Press roller/Creasing cutter/ Kiss cutter/ Punch tip/Drill Spindle | |

| Control system | RD / KINCO / QIANCHENG | ||

| Driving system | Servo motor +Driver | ||

| Transmission | CSK Square guild+Helical Rack | ||

| Work table | Felt auto Feeding worktable+ aluminum sheet | ||

| Feeding stand | Auto feeding stand | ||

| Working speed | 0-1000mm/s | ||

| Compatible software | Coreldraw, AutoCAD, Photoshop | ||

| Minimum character | English 1*1mm | ||

| Position accuracy | ±0.03mm | ||

| Resolution | ±0.1mm | ||

| Working voltage | AC380V ±10%/10A,50-60HZ | ||

| Power | 10KW/H | ||

| Weight | 300KGS | 1200KGS | 1400KGS |